A look inside a few of the hardest working parts on any modern commercial vehicle

Many shock absorbers, from many manufacturers, might look alike from the outside. But it’s what’s inside – beneath the “skin” – that really matters. In fact, overlooking the internal differences and operating characteristics separating one type of axle shock from another could lead to a variety of expensive headaches and lost vehicle productivity.

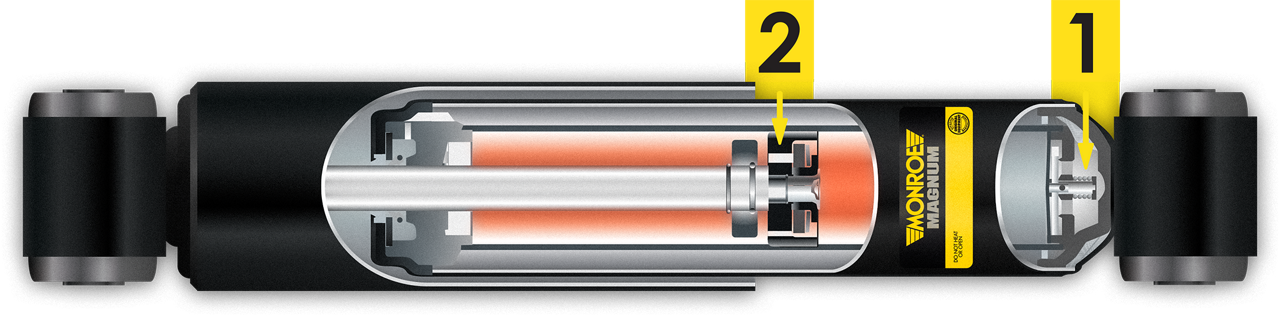

To help highlight these differences, we’ll take an inside look at Monroe® Magnum axle shocks, a leading choice among commercial vehicle fleets worldwide. Monroe Magnum shocks feature a double-action valving system that operates in compression and rebound to help ensure precise, safe handling characteristics. These shocks are also engineered for outstanding durability and best-in-class return on investment.

First, the Basics

A majority of commercial vehicle shocks feature a twin-tube design, meaning there is an inner, pressure or “working,” tube and an outer tube known as the reserve tube, which stores excess hydraulic fluid.

The piston rod within a twin-tube shock passes through a rod guide and seal at the upper end of the pressure tube. The rod guide maintains alignment of the rod within the pressure tube and allows the piston to move freely. The seal retains the unit’s hydraulic oil and helps exclude contaminants such as dirt and water.

The internal valve located at the base of the pressure tube is called the compression valve (see (1) on the picture). It controls fluid movement when the shock is compressed. During a compression stroke, some oil in the lower portion of the pressure tube transfers across the piston via an inlet valve. The remaining oil is forced through a system of orifices within the base valve and then passes into the reserve tube. Key point: The resistive force, or damping, generated by the shock is determined by the speed at which the rod is compressed and the valving technology in the base valve.

Now let’s look at the rebound stroke, meaning the piston rod is exiting the pressure tube and the shock is extending. During this process, the piston’s inlet valve closes and oil in the upper pressure chamber is forced through a valve system within the piston. To compensate for the rod volume exiting the pressure tube, oil passes from the outer oil reservoir into the lower working chamber through an inlet in the base valve. Piston rod velocity and valving (see (2) on the picture) determine the resistive force generated by the shock absorber during the rebound stroke.

Shock absorbers also have a drainage orifice below the seal that allows oil to drain into the reserve tube. This also allows air to escape from the pressure tube, which helps prevent fluid “foaming.”

Bigger means greater control

Bore size is the diameter of the piston and the inside of the pressure tube. Generally, the larger the unit, the higher the potential control levels because of the larger piston displacement and pressure areas. In addition, as piston area increases, the shock’s internal operating pressures and temperatures generally decrease. This also provides higher damping capabilities.

So how are shocks “tuned” to the requirements of a specific vehicle? Ride engineers select valve codes or damping force values for each model to achieve optimal balance and stability under a variety of driving conditions. Their selection of bleeds, deflective valve discs, springs and orifices helps control fluid flow within the unit, which ultimately determines the feel and handling of the vehicle.

Another key design detail is the shock mount – the manner in which the shock will be attached to the axle and vehicle frame. Most quality shocks feature rubber bushings fitted within the mount to help filter out road noise and suspension vibration. These bushings must be flexible to allow movement during suspension travel. But they also must be highly durable, as they’ve got a tough job given the demands of most commercial vehicles.

BUILT TO LAST: MONROE

Now that we understand the basic design and key internal and external elements of a commercial vehicle shock absorber, let’s look at how one brand of shocks uses advanced technology to help deliver better performance and longer service life.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

other articles that might interest you

discover the monroe® range

Discover Monroe shock absorbers, now with a 5 year warranty on any qualifying Monroe product when completing a full replacement of shocks and struts in pairs, including protection and if applicable mounting kits.