A Look Inside Monroe® Magnum Shocks

Why has Monroe Magnum technology gained such widespread popularity among commercial vehicle fleet professionals and technicians? Here’s a quick overview of a few of the “inside” advantages of these units.

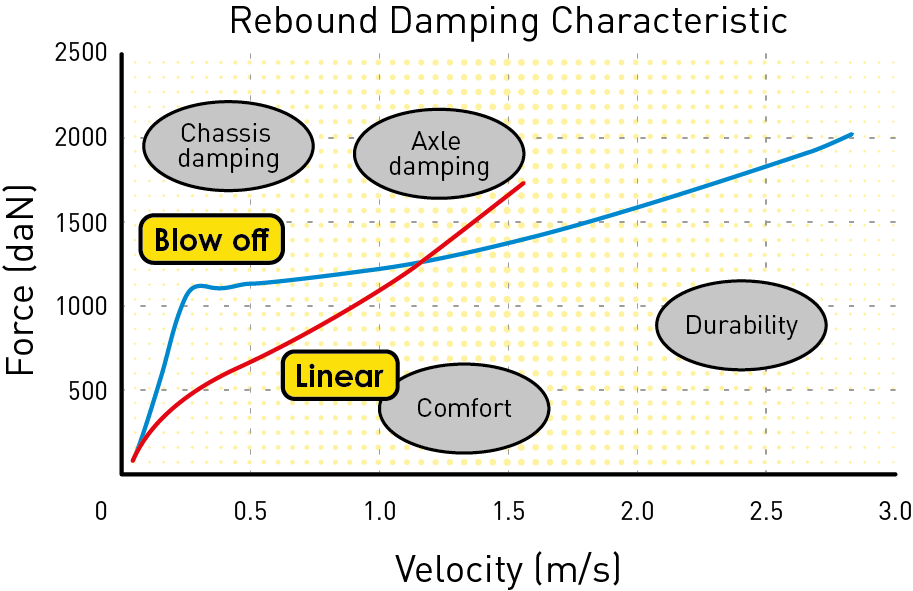

Blow-off rebound valve technology

Monroe Magnum axle shocks include blow-off rebound valve technology that helps provide better control and stability through higher forces at low piston speeds, thereby minimizing body roll. At the same time, the blow-off valve maintains these forces at comfortable levels at high piston speeds.

This technology helps provide a safer ride due to the fact that these “extra” efforts both minimize cabin roll and increase handling and road holding of the truck.

The operation of this valve is really quite simple: Low-speed disks within the valve system provide higher rebound forces than in a normal valve. This produces increased roll control because the valve stops suspension movement more quickly and effectively.

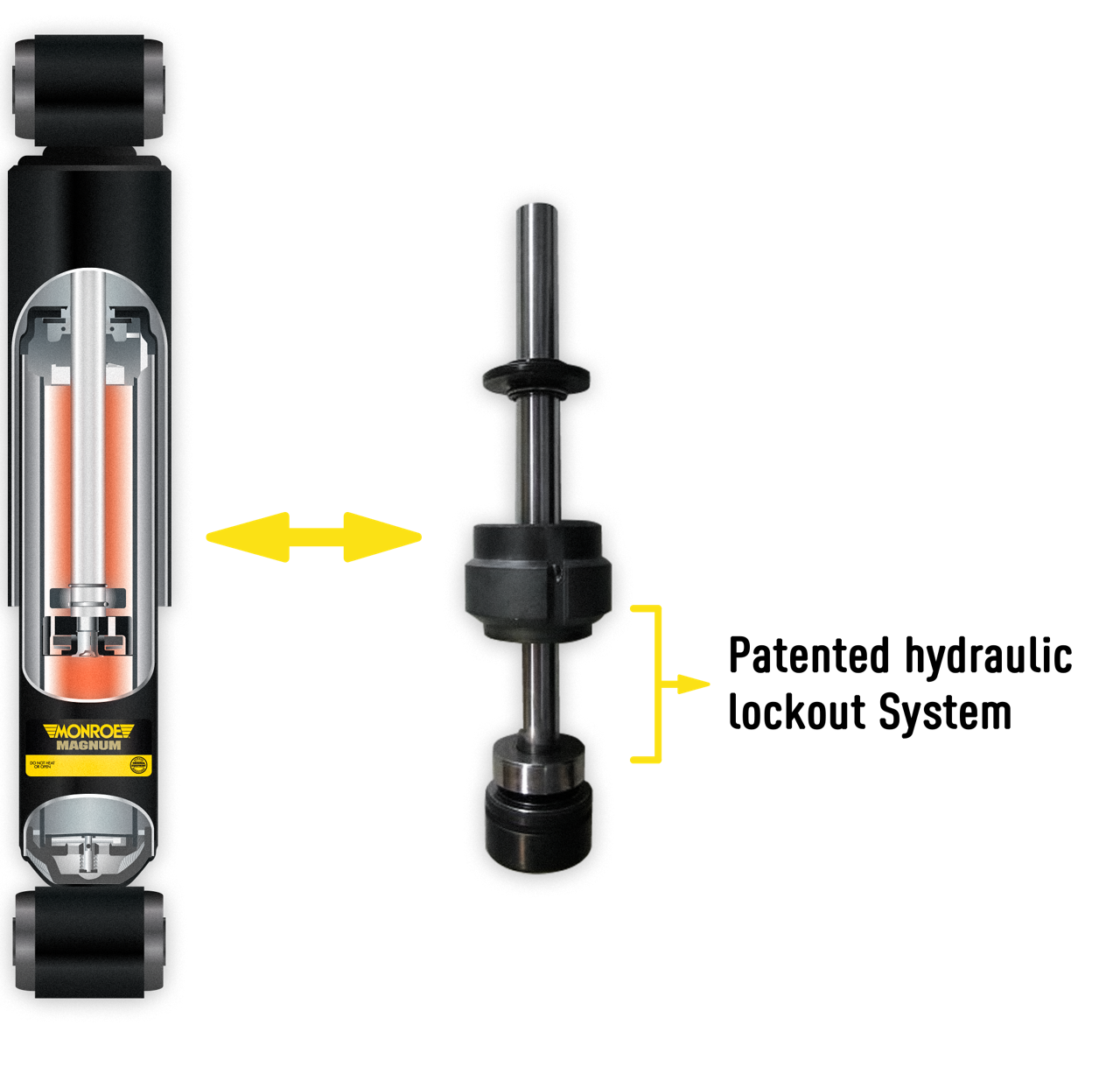

The hydraulic lockout feature

Many Monroe Magnum shocks also include a “hydraulic lockout” feature. Here’s why this matters: on commercial vehicles with air suspensions, the shock absorber helps limit suspension travel, including over-extension of the air spring, which can cause expensive damage.

The hydraulic lockout consists of a patented secondary piston positioned above the valving piston. This design helps transfer mechanical force through the entire diameter of the piston rod, but its primary function is to reduce the velocity at full extension. So, as the lockout piston travels into the extended rod guide, increased hydraulic pressure reduces rod velocity and minimizes metal-to-metal contact at full extension.

Vulcanized silent blocs

Monroe Magnum shocks include a type of mounting bushing known as “Vulcanized Silent Blocs.” Remember, the function of the bushing is to ensure a strong, elastic linkage between the shock absorbers and chassis while filtering out vibrations. The performance and durability of this critical component are directly related to the quality of the rubber used in the manufacturing process and whether that material has been vulcanized over the sleeve.

The use of the wrong rubber composition could lead to premature destruction of the bushing, leading to increased vibration and potentially accelerating wear of the tires and other components. Bonded bushings – the technology featured in Monroe Magnum shocks – feature rubber that has been vulcanized, or hardened/cured, over the sleeve. This design is more resistant to wear and offers better vibration isolation and longer service life.

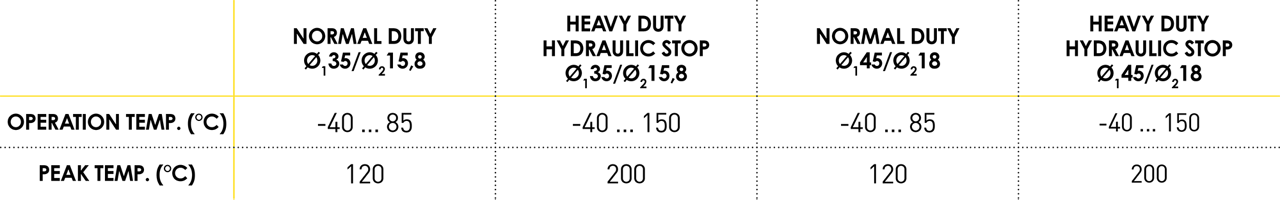

High-quality oil seal

A high-quality oil seal is absolutely vital to shock durability. Failure of the seal can allow hydraulic oil and/or gas to leak from the unit. A bad seal can also permit dirt, grit and other contaminants to enter the shock. This elastic element should be designed to withstand strong friction forces and high temperatures. Monroe Magnum shock absorbers feature an advanced Viton double-lip high-temperature-resistant oil seal designed to minimize leakage and help extend operating life under even the most demanding working conditions. In fact, this seal allows Magnum shocks to maintain excellent performance in temperatures up to 200º C.

Specifically engineered semi-synthetic oils

The choice of the right oil for each commercial vehicle shock is a key factor that will determine performance and durability. Monroe Magnum shock absorbers feature specially engineered semi-synthetic oils formulated for challenging operating environments. Monroe design engineers select the specific oil for each shock based on the unit’s valving, diameter of the internal oil chambers, anticipated vehicle loads, operating ranges, stroke length and other key characteristics.

Coated rebound valves

A truck shock performs an average of around 132 million cycles every 120.000 km. This movement generates contact-related wear between the piston surface and the wall of the working chamber. In particular, this contact can generate areas of permanent damage over the anti-friction piston ring, which can then contaminate the oil and create potential leak paths.

Piston wear produces changes in a shock’s rebound and compression forces and resulting deterioration of a truck’s road holding and stability characteristics. It can also lead to reduced tyre life in some situations.

To reduce these risks, Monroe Magnum shock absorbers are equipped with rebound valves that are coated with a highly advanced and extremely effective anti-wear material.

Protective paint coating

Even the shock’s outer “skin” – its protective paint coating – can be an important differentiator. Keep in mind that shocks are often subjected to brutal conditions, including exposure to road salt and other corrosives. Monroe Magnum shocks are painted using a high-quality electrostatic process that attracts paint molecules to all metallic surfaces, ensuring outstanding coverage, consistency and protection. Once the shock housings are correctly coated with paint, they receive a thermal treatment for added hardening.

Every shock is different

Just as all shocks are not the same, commercial vehicles can vary widely in terms of operating demands. Each also has unique design configurations: leaf springs, air springs, height, total weight, engine power, etc. For this important reason, each Monroe Magnum shock absorber is individually engineered to meet the requirements of the corresponding axle and vehicle. This ensures that each shock provides a vehicle-specific ride experience, with superior hydraulic characteristics for a given use.

Which shocks do commercial vehicle manufacturers use?

The answer to this question can be an excellent guide in selecting the best replacement shock. Vehicle manufacturers are extremely careful in selecting the parts – and suppliers – featured on each vehicle. After all, it’s the OEM’s reputation that is on the line. Monroe shocks are factory installed by many of the industry’s leading truck, trailer, bus, axle and equipment manufacturers, including BPW, Claas, CNH, Daf, Daimler, Dennis, Foden, GAZ, Hendrickson, ISRI, Leyland, Mercedes-Benz, Nissan, Renault, RVI, Setra, Volvo, and Zetor.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

other articles that might interest you

discover the monroe range

Monroe offers a total steering & suspension solution for vehicles. Discover our shock absorbers, mounting and protection kits, gas springs, coil springs, spheres

and many other steering & suspension parts.