ServiceGram Vol. 1, No. 6

Avoiding Strut Assembly Installation Noise Issues

Challenge:

Strut Assembly Installation – Avoiding Noise Issues

Monroe shock absorbers and struts are precisely tuned to withstand immense pressure, but – like any other vehicle component – they can fail prematurely when installed incorrectly. Though no visible exterior damage may be present, using the wrong tools for the job can cause severe damage inside the shock and result in an unhappy customer.

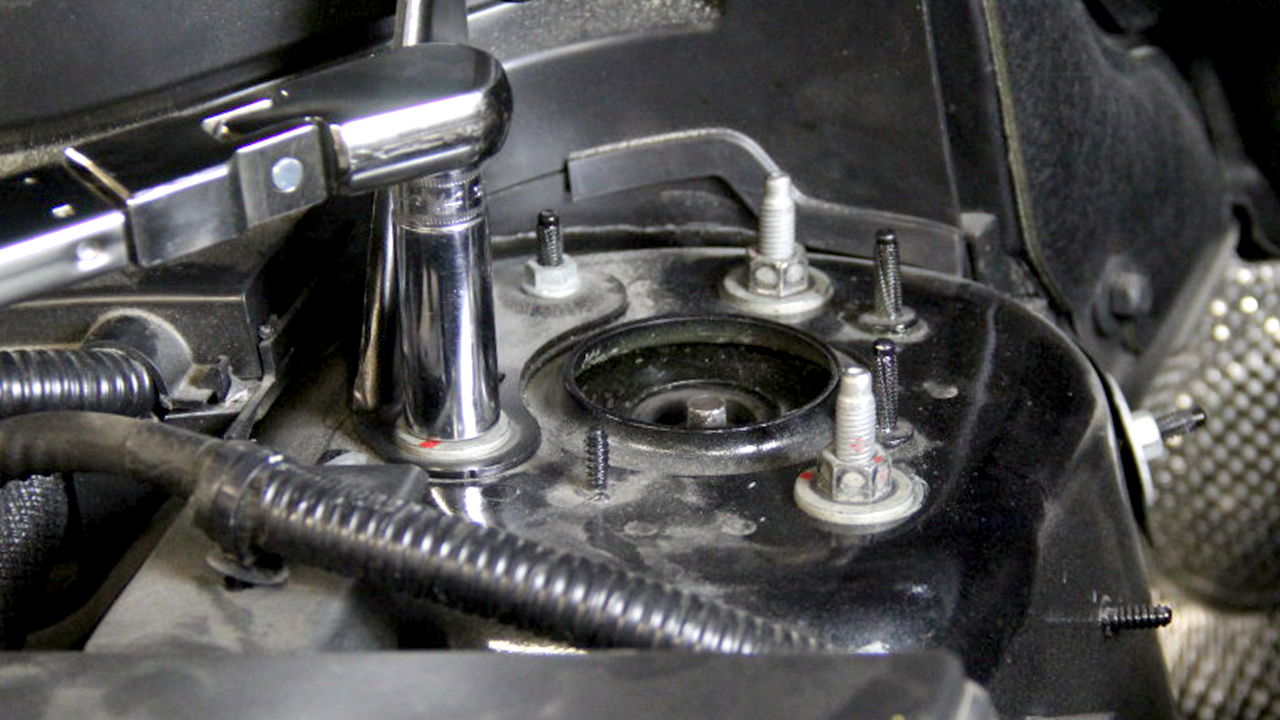

Noise can occur due to improper mount loading during installation. This can result in mount damage or a crushed bearing. Stretched or broken studs also can be the result of fully securing the mounting nuts prior to placing the weight of the vehicle on its tires.

Solution:

Proper installation procedure for strut assemblies:

Step 1

Loosely install one or two upper mounting nuts to hold the strut assembly in place. Then position the lower strut mount to the steering knuckle assembly. This prevents the strut mount from binding or damaging the strut bearing.

Step 2

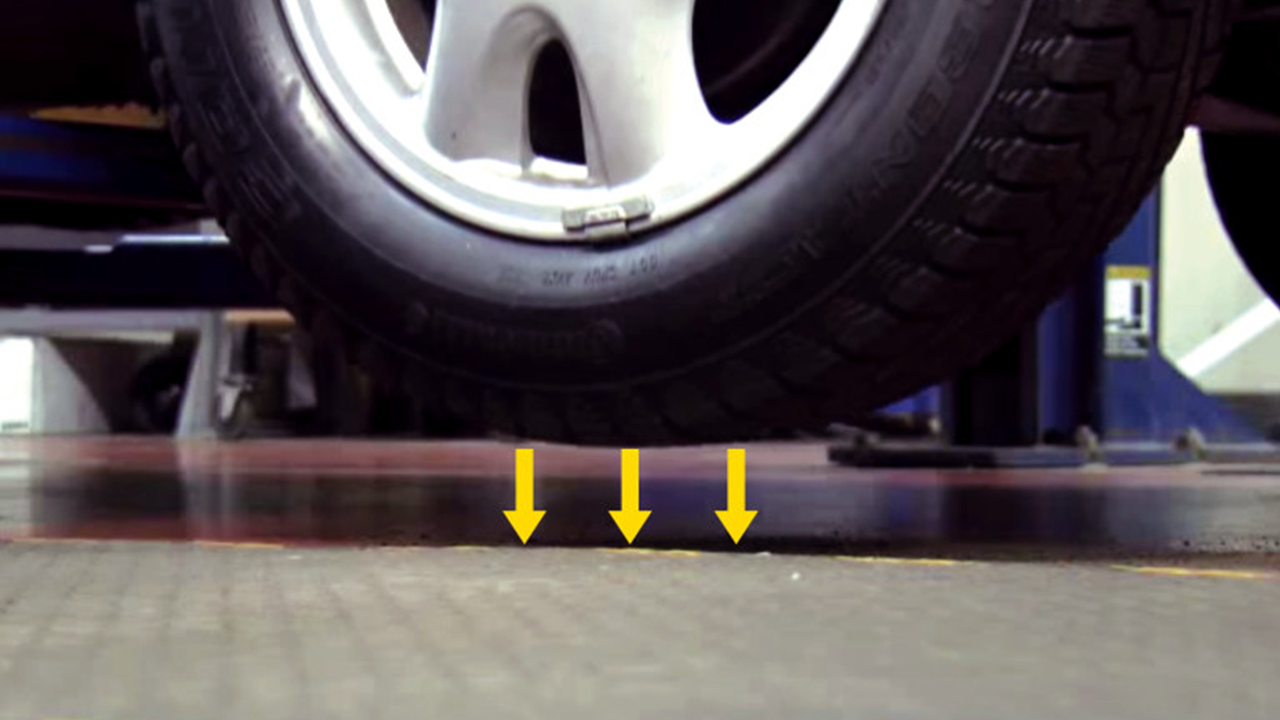

Install lower mounting bolt(s) and lower the vehicle so that the weight of the vehicle rests on the tires.

Step 3

Check vehicle manufacturer specifications to determine proper torque values.

Step 4

After torquing the lower mounting bolts, secure the upper mounting nuts in an alternating pattern until all are fully tightened with a torque wrench.

Learn more about quality suspension parts, find the right car part, or find a local repair shop today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.