The value and importance of mounting kits

Replacing worn shock absorbers and struts is a proven way to help enhance vehicle comfort, handling and safety. But as with any important repair, this one must be done correctly to help ensure long component life and an outstanding driving experience. New shock absorbers and struts should always be installed in pairs. In addition, each new unit should be protected with a new protection kit. And finally, when replacing struts, do not forget to also install new mounting kits from Monroe®.

This article will focus on the purpose and design of strut mounting kits and reasons why a new mounting kit should be installed with each new strut.

First things first: shocks vs. struts

Shock absorbers and struts perform many of the same functions, but struts play an important additional role in today’s vehicles. Unlike conventional shocks, struts are structural components within the vehicle’s suspension – they help carry the weight of the vehicle. As a result, struts feature more robust construction and require specialized mounting hardware. Read more about shocks vs. struts.

Another type of shock, the spring seat shock absorber, is similar to a strut in that it helps suspend the vehicle’s weight. A key difference, however, is that a spring seat shock is not subjected to significant side loads and therefore typically will feature less robust construction.

WHAT IS A MOUNTING KIT?

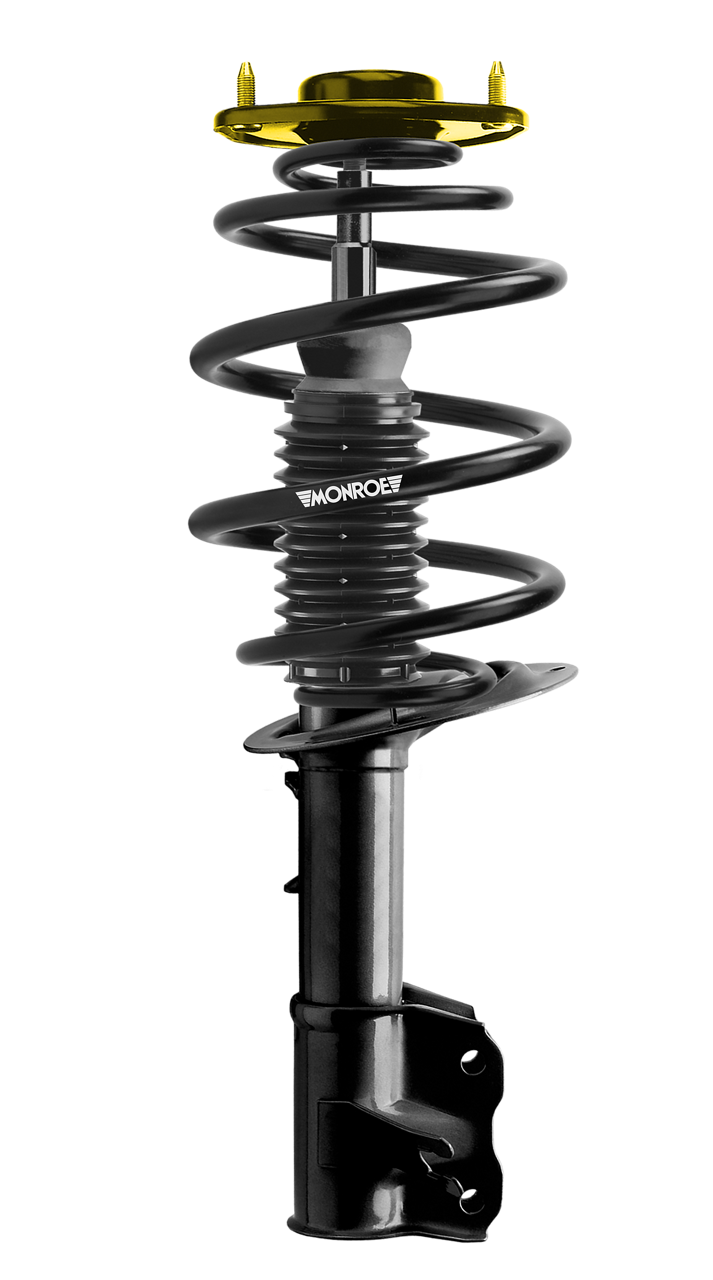

The mounting kit serves as the upper connection between the strut and the vehicle’s body. It also plays a central role in ensuring smooth, precise steering and a vibration- and noise-free ride. Mounting kit contents include:

- Mounting Kit for MacPherson struts:

The lower end of a MacPherson strut is connected directly to the wheels through the steering knuckle and must smoothly rotate as the wheels are turned. As a result, most mounting kits for MacPherson struts include two components: a rubber block and high-strength bearing.

- Mounting Kit for spring seat shocks:

Spring seat shocks are not connected to the vehicle’s wheels and therefore do not rotate as the wheels turn. As a result, mounting kits for these shocks do not include a bearing.

Rubber block

The rubber block within a mounting kit, sometimes referred to as the “filtering block,” is constructed from a high-quality rubber compound and is intended to filter out road vibrations. Suspension performance is directly linked to this block (and bearing, when applicable) because it helps provide load support, absorb small road irregularities, guide strut rotation and maintain proper wheel alignment.

As these rubber blocks wear out, they become harder, losing their elasticity and absorption qualities. As a result, they cannot effectively isolate noise, vibration and harshness from the cabin and steering wheel. Dynamic testing demonstrates that a worn-out block can have a profoundly negative effect on ride comfort. Compounding the problem, these vibrations can also lead to accelerated wear of the strut steering ball joints and silent blocks.

Vibration issues after replacing the struts are often misdiagnosed as wheel balancing problems, so it is important for technicians to remember to also inspect the vehicles’ mounting kits.

BEARING

Mounting kits for MacPherson struts also include a bearing, which is designed to guide the strut’s rotation as the steering wheel is turned. As bearings wear out, they produce excess friction, which increases the effort required to turn the wheel, particularly at low speeds, and often generates a “knocking” sound each time the vehicle accelerates or brakes. A bearing which is still in use after 130.000 kilometers of service can require a steering system to exert 10% to 20% more effort to turn the wheel as compared to a new bearing.

More importantly, worn out or defective bearings are unsafe, as added friction impedes the strut’s ability to help the vehicle recover a straight line after turns and curves. This means drivers must be more attentive and make frequent and unexpected course corrections.

Inspect and replace

The maximum working life of a mounting kit is approximately 80.000 km. To ensure optimal performance, Monroe recommends conducting an inspection every 20.000 km and replacing the kit immediately if damage or wear is identified.

Monroe also strongly recommends installing new mounting kits with each strut replacement. Never reuse existing mounting kit components as they can degrade suspension performance and might result in loss of warranty coverage on the new struts.

Always choose the best: Monroe

While most mounting kits might look similar on the surface, there can be significant differences in the materials used by their manufacturers, which can affect quality and performance. Monroe Mounting Kits are manufactured from original equipment grade materials, ensuring they help reduce road-induced noise and vibrations, provide a smooth ride and deliver precise, jump-free steering.

Most important, these high-quality kits are a perfect complement to Monroe struts. Together these parts deliver the world-class ride experience preferred by millions of installers.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

Additional tips for protecting suspension systems

Extend shock absorber life by always installing in pairs

In addition to mounting kits, there are additional best practices installers should follow to ensure that new suspension components are fully protected and equipped to deliver longer-lasting, safe performance. Prevent adverse suspension performance and premature wear of components when installing new shock absorbers by installing shocks and struts in pairs.

discover the monroe® range

Discover Monroe shock absorbers, now with a 5 year warranty on any qualifying Monroe product when completing a full replacement of shocks and struts in pairs, including protection and if applicable mounting kits.