Shocks 101

What Causes Shocks & Struts to Wear Out?

How Shocks & Struts Wear Out

Having shocks and struts that are in top operating condition helps keep your vehicle’s tires in contact with the road, improving the stopping, handling and safety of your vehicle. Just like most of the parts on your vehicle, shocks and struts are subject to wear and must be periodically replaced to maintain optimum performance. Read on to learn how shocks and struts wear out:

Damaged Bushings

Rubber bushings reduce noise and vibration, and when they become damaged or worn this can contribute to excessive movement. This, in turn, may cause premature wear to not only shocks and struts but also to tires and other suspension parts. Worn bushings can cause problems like noise, excessive bouncing and poor handling.

Friction, age, high temperatures, weight load stress and exposure to salt and oil can cause bushings to crack and wear. When bushings wear, it puts additional stress on the connected parts which can affect a range of things like alignment. Damaged or worn bushings are not always obvious, so be sure to have your service provider examine the bushings on your steering and suspension system on a regular basis. Having properly working bushings makes a big difference in the ride and handling of your vehicle.

Worn Internal Oil

Shocks and struts are filled with oil to control unwanted spring motion in a process called damping. As the piston in the shock or strut moves up and down, the oil heats up, damping the motion. The oil in your shock or strut goes through this heat cycle countless times as you drive down the road.

Over time, the oil in your shocks and struts can lose its viscosity due to the heat cycling. Notice in the image the comparison of new oil on the left and oil after 50,000 miles on the right. As this break down occurs, the oil will lose its ability to properly lubricate internal components, and can adversely affect the ability of your shocks and struts to mitigate the impacts of the road. When this happens, having your shocks or struts replaced will help restore your vehicle’s ride, handling and stopping power.

If the oil level is significantly reduced, or overheated, it can allow the oil to coat the internal moving parts with a varnish-like film, which prevents smooth operation of the unit and leads to a harsher ride.

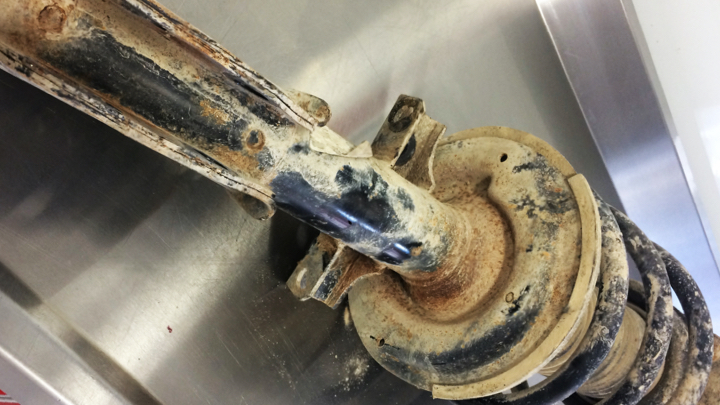

Deteriorated Components

With repeated use, internal components of your shocks or struts can fatigue. As the valving components decline, they lose their damping effectiveness, impacting the shock or strut’s overall performance. This failure, which can happen with age or as a result of an impact or accident, limits control of excessive body and tire movement.

Once the components begin to deteriorate, having your shocks or struts replaced is the best way to acquire like-new ride, braking, and handling. Shocks and struts can’t be repaired; replacing the affected part is the best solution. Don’t wait to replace a failing shock or strut, as you risk a continuing loss of ride, handling and braking performance as the parts degrade.

Additionally, other critical structural components of the shock or strut may fatigue, leading to a potential loss of tensile strength. Components such as brake line brackets, anti-sway bar brackets, steering arms welded to strut bodies, and upper and lower welds which hold mounts in place, may not have the strength that is required to keep them from failing under harsh impacts.

If the vehicle encounters a harsh impact, like a large pothole or curb, the shock or strut body or rod may become bent, which may cause the alignment and steering geometry to be out of spec. This can lead to accelerated tire wear and unusual steering response.

Learn more about quality shocks, struts, and strut assemblies, find the right car part, or find a local repair shop today.

The content in this article is for informational purposes only. You should consult with a certified technician or mechanic if you have questions relating to any of the topics covered herein. Tenneco will not be liable for any loss or damage caused by your reliance on any content.